High-molecular Polymer

Feature

Technological Advantage

The new continuous production line requires less equipment than the traditional intermittent production line, which greatly reduces the capital cost.

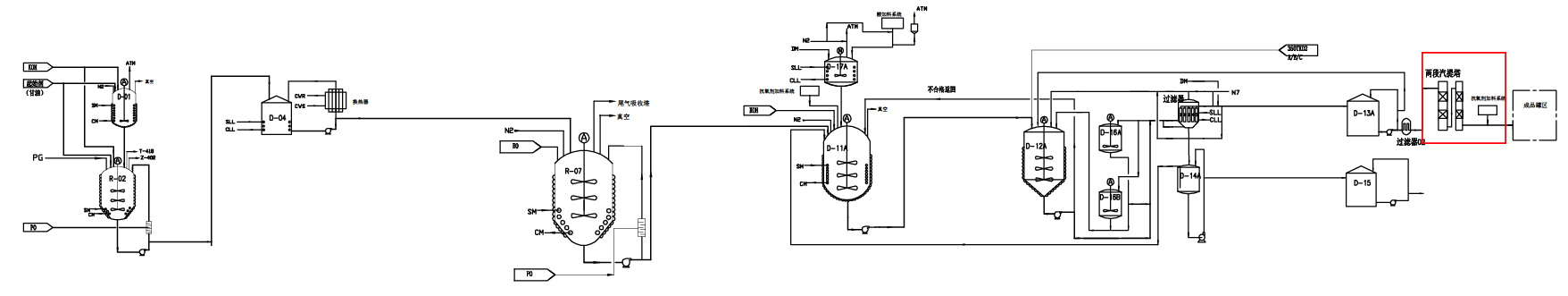

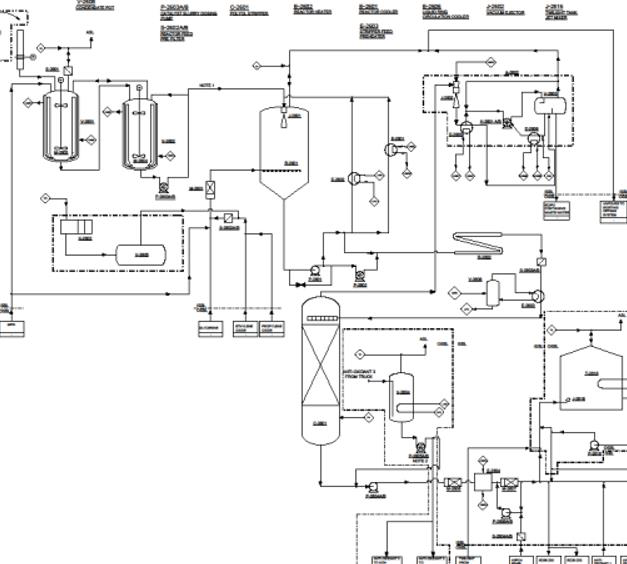

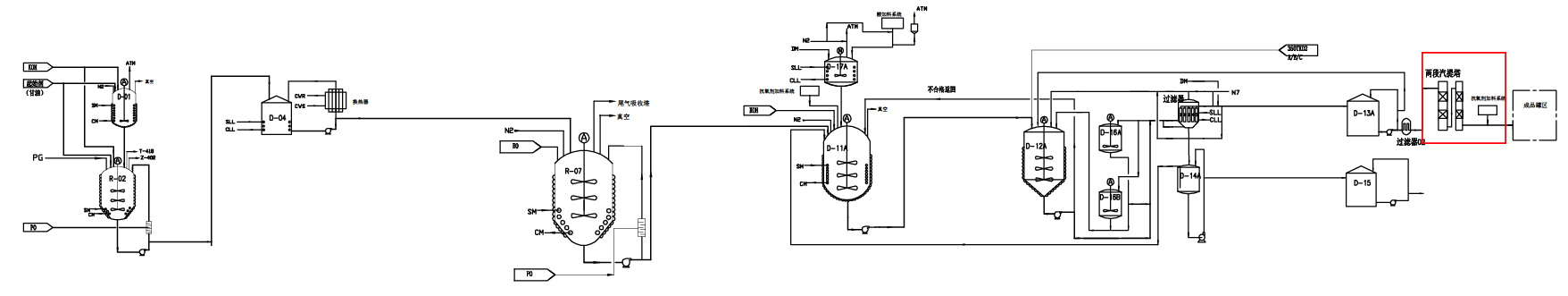

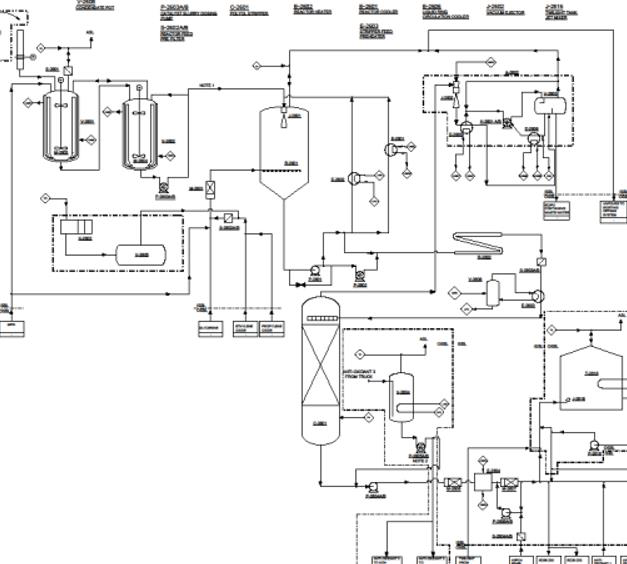

The typical flow of traditional KOH catalytic process and continuous polymetallic catalyst process is shown below

Higher conversion of propylene oxide (PO)/ethylene oxide (EO), resulting in higher feedstock efficiency and less organic waste;

Highly active catalysts with very low usage are retained in the product, so no catalyst waste is generated;

The continuous production process is more energy efficient than the intermittent process because there are not many energy-intensive evaporation steps.

The lower levels of impurities in the reaction products combined with the removal steps provide an excellent product in terms of odor composition and volatile organic composition;

The continuous operation mode of the continuous production process helps to achieve higher reliability than traditional batch processes.

The continuous production process is inherently safer because the PO concentration in the reactor in a steady state is low, usually around 1%.

Product Type

The new continuous production line requires less equipment than the traditional intermittent production line, which greatly reduces the capital cost.

The typical flow of traditional KOH catalytic process and continuous polymetallic catalyst process is shown below

KOH catalytic process

Continuous polymetallic catalyst process

Higher conversion of propylene oxide (PO)/ethylene oxide (EO), resulting in higher feedstock efficiency and less organic waste;

Highly active catalysts with very low usage are retained in the product, so no catalyst waste is generated;

The continuous production process is more energy efficient than the intermittent process because there are not many energy-intensive evaporation steps.

The lower levels of impurities in the reaction products combined with the removal steps provide an excellent product in terms of odor composition and volatile organic composition;

The continuous operation mode of the continuous production process helps to achieve higher reliability than traditional batch processes.

The continuous production process is inherently safer because the PO concentration in the reactor in a steady state is low, usually around 1%.

Product Type

- Soft foam polyether polyol

- Hard bubble polyether polyol

- Combined polyether

- CASE polyether polyols

Application

Contact Us

We are here for you